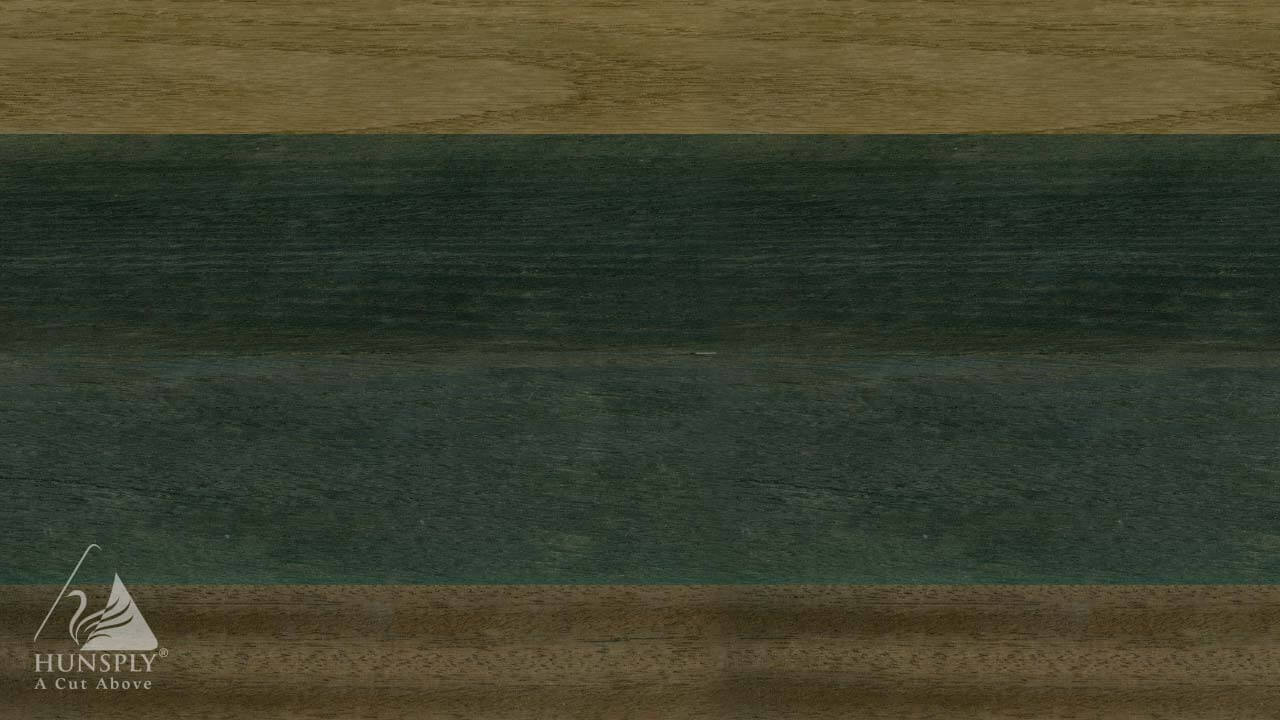

Weaved veneer is a mix of two different grains of veneer or two entirely unrelated genres of veneer, woven together to give a pleated appearance. Not only is the job labour intensive but it requires a skilled craftsmanship to be produced. Two or more kinds of sliced veneer, not less than 1 inch in width are intertwined in a spell bounding pattern and then taped and pressed onto the desired surface eg. plywood or fleece. Usually bamboo was the veneer of choice but nowadays is considered a passé. Presently, almost all kinds of veneer can be used for this process.

How Veneers Are Processed At Hunsply