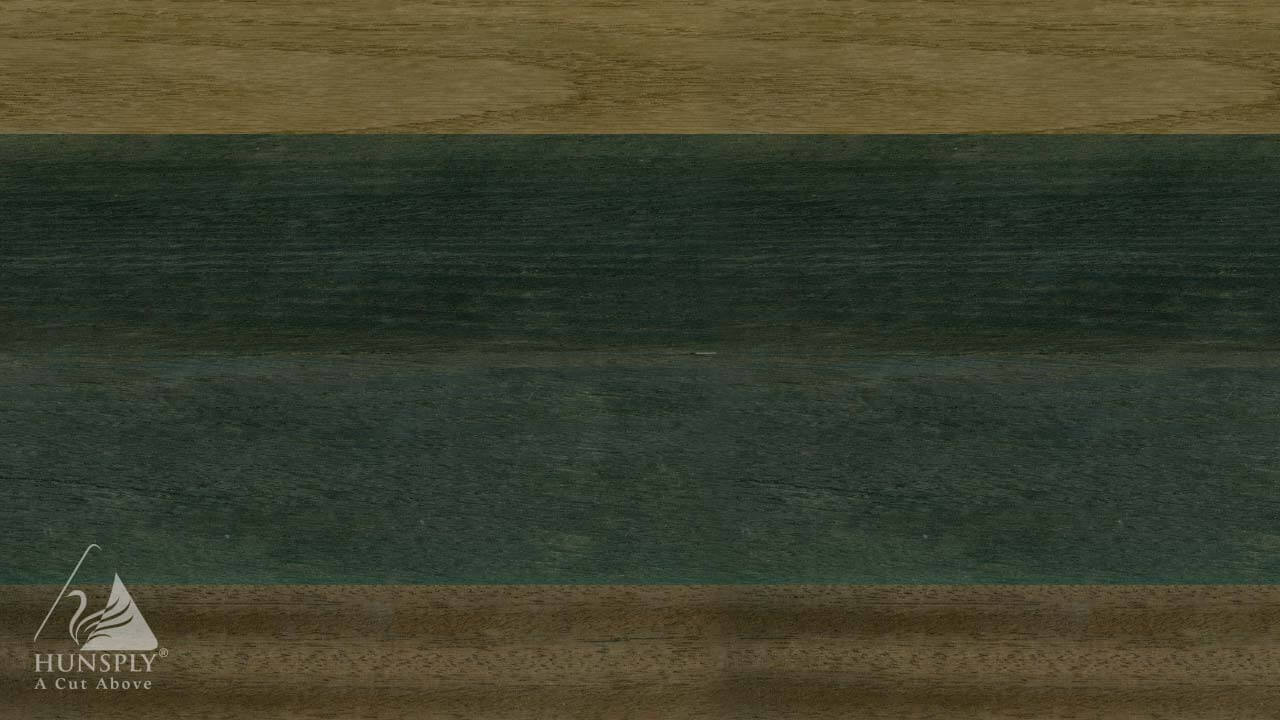

Stained dark colored Veneers are in vogue these days. The process used for manufacturing turns light colored veneers to warm rich chocolate browns. Very few kinds of wood can be processed in this fashion as there is a definite level of tannic acid required. This tannic acid reacts with the fuming ammonia to produce the dark hues of brown. The colour that the fumed wood takes on due to the fumigation process is to a large degree non-aging and is far more stable to light compared to many other coloured wood types. The fumed wood veneer is also more elastic and less brittle.

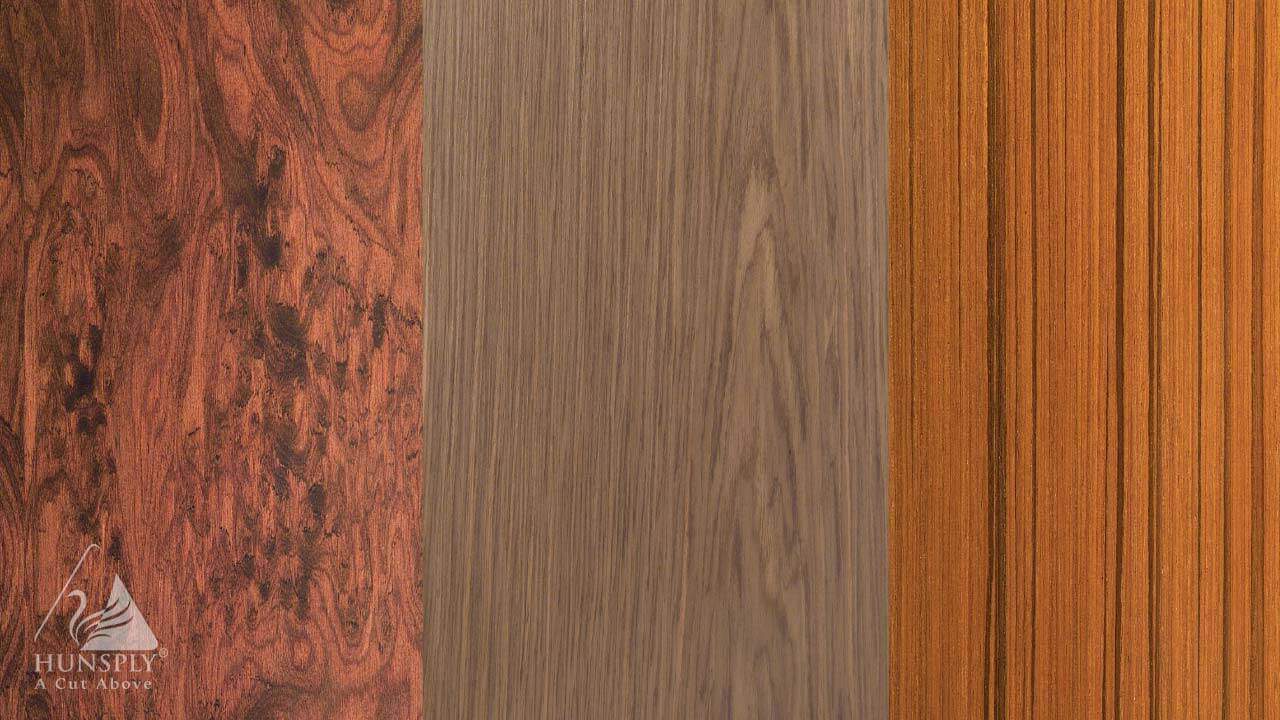

How Veneers Are Processed At Hunsply