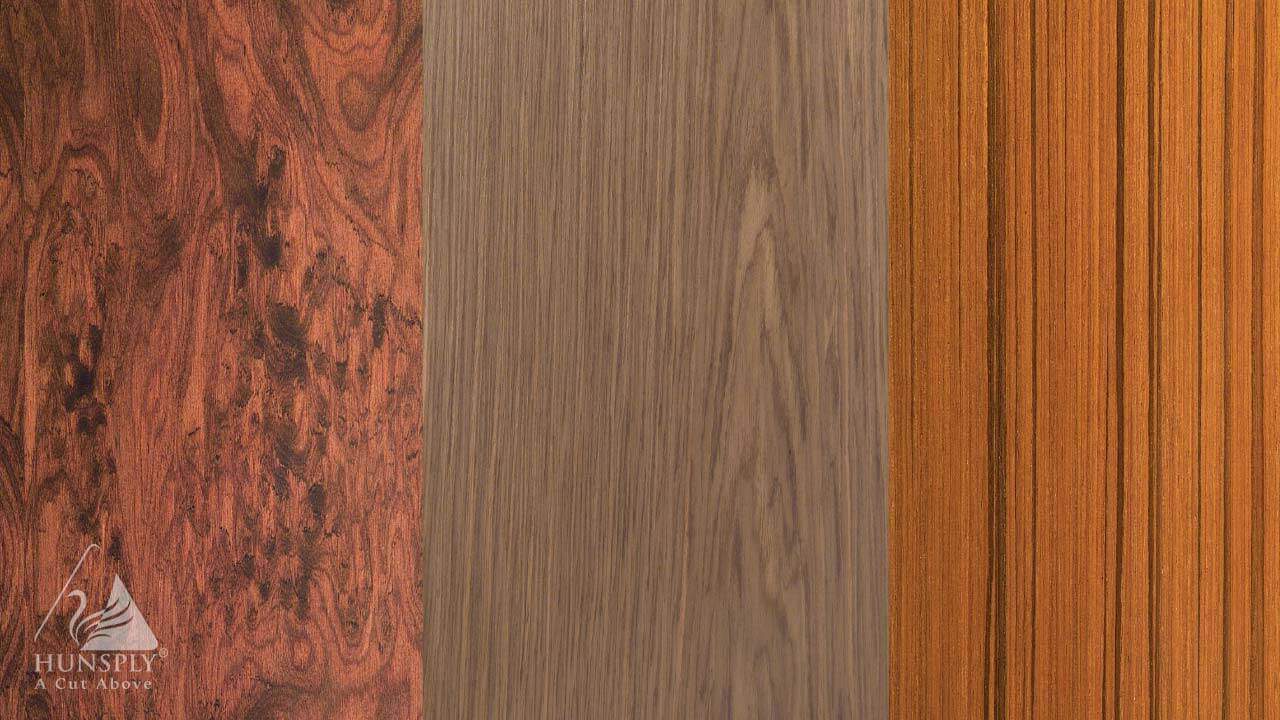

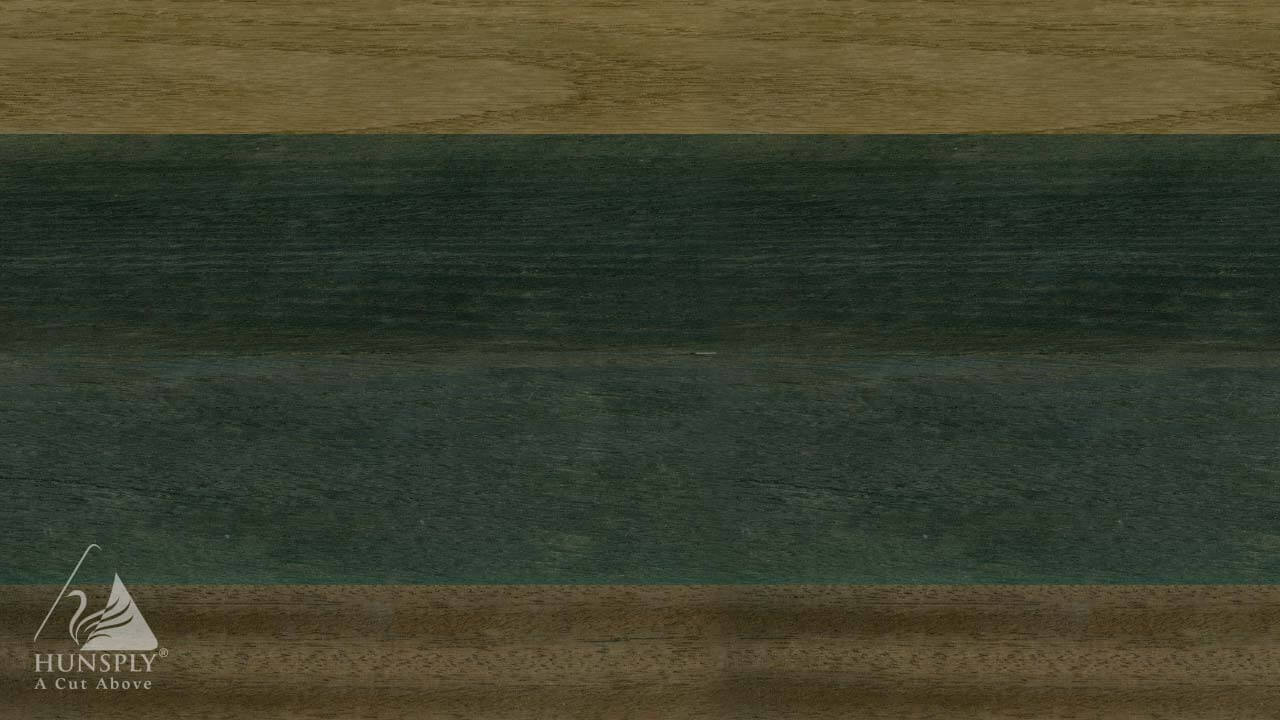

This kind of veneer requires intensive manpower and creativity. It is not just a natural veneer sliced out of a log.The barks are peeled and converted to thin sheets by a peeling machine. The slices are then dyed to desirable shades.Most of this process is automated and carried at specific temperatures with water soluble dyes mostly organic by nature. According to the desired figure, the sheets are arranged and piled for pressing.Then they are glued by rollers and allowed for pressing in specific press according to desired designs. The blocks are then suitable squared and sanded . After which they are sliced to .4mm to almost 2mm thickness and inspected for retailing.

How Veneers Are Processed At Hunsply